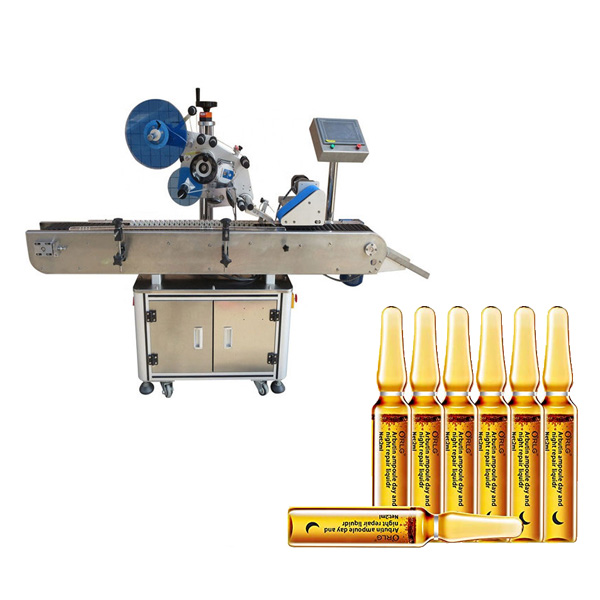

High speed automatic vertical ampoule labelling machine model the labelling machine is fabricated under rigid supervision, keeping in view the strict gmp standards for use in pharmaceutical and allied industries. Very strict quality control standards adopted during the manufacturing process ensure trouble free operation and need minimum maintenance / shutdown time. The high out put of the machine saving production cost and also saves valuable time. The automatic ampoule labeling machine has variable ac frequency drive system for smooth control of the machine for required out-put upto 220 ampoules per minute. The machines having online batch printing. The super silent machine has minimum noise pollution and thus result in increased productivity amongst the work force. Inclined in-feed hopper ensures uniform flow of objects for labeling.

Automatic ampoule sticker labeling machine for high speed wrap-around application on ampoules. The ampoule sticker labeller incorporates with modern micro processor control label dispensing system with user friendly sensing system for label and product. The ampoule sticker labelling machine is suitable for labeling on round vials, and other round objects. It is capable of labelling up to 200 units per minute depending on products and label size. Specially designed electronic and mechanical system to apply transparent (no look) labels on vials at very high speed using optional special label sensing system.truly one and only high-speed rotary warp around labelling machine available, with unique single point synchronized speed control system. The inbuilt automated label length detection systems eliminates any need for manually feeding and storing of label length data in memory and retrieving the same every time for change of label size & re-starting the machine. The system thus saves valuable time, avoiding machine-down time, and helps achieve higher production.

What is ampoule?

An ampoule (also ampul and ampule) is a small sealed vial which is used to contain and preserve a sample, usually a solid or liquid. Ampoules are made of glass.

Modern ampoules are most commonly used to contain pharmaceuticals and chemicals that must be protected from air and contaminants. They are hermetically sealed by melting the thin top with an open flame, and usually opened by snapping off the neck. The space above the chemical may be filled with an inert gas before sealing. The walls of glass ampoules are usually sufficiently strong to be brought into a glovebox without any difficulty.

When you need an ampoule labeling solution, VKPAK provides the following products to meet your requirements