Introduction

Sticker Labeling machine for cup , also called top labeling machine, designed for top labeling on flat products, such as cups, paper box, bottle lid, mobile phone screen panel, CD box, bread etc. It can be connected with one production line or operated separately.

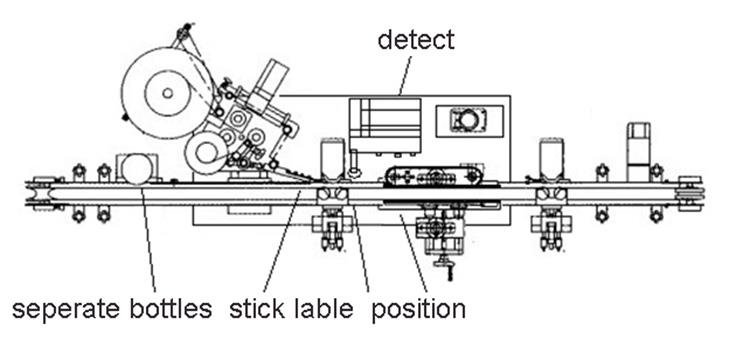

Adopt PLC control, with LCD touch screen operate, setting and operate is clear and easy. Whole process include guiding, separate, labeling, counting, etc, The labeling position can be adjusted.

Technical parameter

| Labeling speed | 2000bph,adjustable |

| Bottle diameter | Below 120mm |

| Label width | 10-200mm |

| Label length | 10-400mm |

| Labeler error | ≤ ±0.5mm |

| Label Roll Diameter | Reel Inner diameter: 76mm; Reel outer diameter: Max 360mm |

| Net weight | 300kg |

| Contour Sizes | 2000*900*1700mm |

Technical Features and application:

1. Applicable to automatically separating and labeling cup top surface or pages of unformed paper boxes.

2. The vacuum conveyer belt takes cups or other products onto it automatically avoiding products translocation. It can separate cups stably and accurately;

3. adopts PLC control system to ensure the stable running

4. Speed regulation can be adjusted for labeling, conveying, cups separating as needed;

5. Labeling is performed smoothly with no creases with the use of elastic cotton idler wheel;

6. Automatic photoelectric detection functions including cancelling labeling without cups or products passing.

Device Characteristic

- Adopt mature technology PLC control system, operation is stable andhigh-speed;

- Using touch-screen man-machine interface operating system, simple and efficient;

- Synchronization chain mechanism ensure labeling smooth and precise;

- OCR detecting system and Sub-quality products reject system, After though the OCR detecting system find the labeling position have a little deflection, then this product will be reject

- Imported electric elements, stable performance, low failure rate;

- Adopting photoelectric detection, PLC control system, software operation, conveyor belt, labeling accurately and high precision;

- No objects not labeling, automatic alarm when achieve leakage label.

- The whole machine use the material of S304 stainless steel and anodized senior aluminum alloy, with high corrosion resistance and never rust;

Main Electrical Configuration :

| No | Name | Unit | Brand |

| 1 | PLC control system | 1 Set | SIEMENS |

| 2 | Touch-screen | 1 Piece | SIEMENS |

| 3 | Servo motor | 2sets | America AB |

| 4 | Drive | 2sets | America AB |

| 5 | Frequency converter | 1 set | SIEMENS |

| 6 | photoelectric sensor (check bottle) | 1 set | Japan KEYENCE |

| 7 | Photoelectric sensor (Check opaque label) | 2 sets | German Leuze |

| Photoelectric sensor (Check opaque and transparent label) | 2 sets | German Leuze | |

| 8 | Main transport motor | 1 set | Switzerland ABB |

| 9 | Separate bottle Motor | 2 sets | German JSCC |