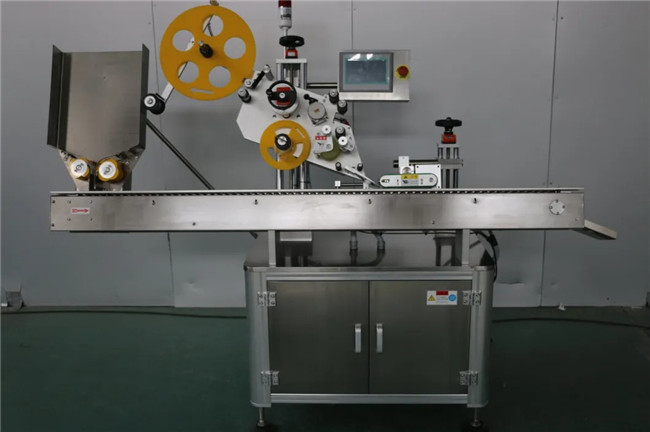

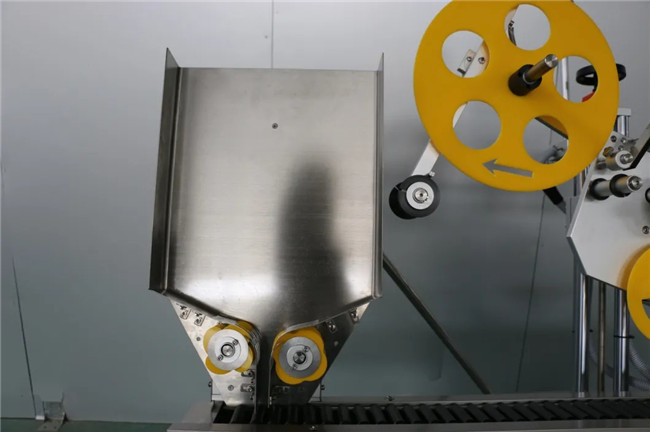

Automatic horizontal wrap sticker labeling machine or unstable round product wrap labeler utilize a roller bed type of conveyor in order to lay smaller diameter products on their side and apply labels around the circumference. Horizontal wrap labeling systems can be hand fed with an infeed chute or fully automated with infeed and discharge magazines, products are fed manually or automatically on the roll conveyor bed, travels under a wrap belt assembly where the label is dispensed onto the products. The rotating motion of the belt spins the product in the roller pocket and the label wipes down. Typical products for the horizontal wrap labelers are vials, pens, lip sticks, crayons, inhales, glue sticks, syringes, test tubes, sausages, batteries, ampules, chopsticks and other small diameter cylindrical plastic or glass containers.

The Scope of Application:

Applicable for round objects with smaller diameter whihc can not stand when labeling,such as ampoule ,vials,blood collection tube, pen,sausage and so on.

(P.S. our labeling machine can be designed according to your needs)

Device Advantages:

- Imported electric elements, stable performance, low failure rate;

- Adopt photoelectric detection, PLC control system, software operation, conveyor belt,

- Label accurately with high precision;

- No bottle no label, automatic alarm when achieve leakage label.

- The whole machine use material S304 stainless steel and anodized senior aluminum alloy.

Automatic horizontal wrap vial labeling/labelling machine is is made of 304 stainless steel and anodized aluminum, and carefully treated to guard against the effects of harsher environments, comes with an angled roller chain conveyor ensuring accurate labeling by securing the product on its side as it moves through the label head and a hopper feeder to load products onto the conveyor, the label head is fully synchronized with the conveyor. Additional features include PLC control and user friendly HMI, powered assisted web take up, non-contact product sensor for label gaps and containers and optional build back sensor.

Key Features

♦ Heavy-duty stainless steel constructed anodized aluminium components

♦ Electronic components are world famous brand

♦ Applying labels on slim,unwieldy, non-freestanding, round containers

♦ Variable speed bottle infeed seperator wheel

♦ PLC control and user friendly HMI

♦ Servo motor drive delivers accurate and high-speed repeatable labeling

♦ Automatic synchronized label head and conveyor belt

♦ Power assisted web take up

♦ Low or missing label detection with automatic stop system to prevent mislabeling

♦ Non-contact photo eye sensors

♦ Label counter

Available Options

♦ Hot stamp printing coder with base (prints characters directly onto the label)

♦ Clear Label Sensors (capable of detecting transparent labels)

Technical Specifications

| Driving Mode | German Avery brand |

| Yield(pcs/min) | 30-200 |

| Operating direction | Left or Right |

| Conveyor Speed(m/min) | ≤30 |

| Labeling Accuracy | ±1.0 mm |

| The inner diameter of label roll | 76 mm |

| The outer diameter of label roll | 350 mm(max) |

| The suitable label size | Width 10-110 mm length 5-120 mm |

| The suitable size of labeling objects | Can customized depends on client product |

| Printer use air | 5kg/cm ² |

| Voltage (In China) | AC220V 50/60HZ Single phase (Can customized as client need) |

| Power(w) | 600W |

| Weight(kg) | 260 |

| Machine size | 1800(L) 800 (W) 1300 (H) mm |