This shrink sleeve labeling applicator function is for PVC label shrink on the bottle ,used for beverage bottle package solution ,international advanced technology ,cover the circle label on PET bottle ,And then hot shrinking to fix on the position which bottle body designated.

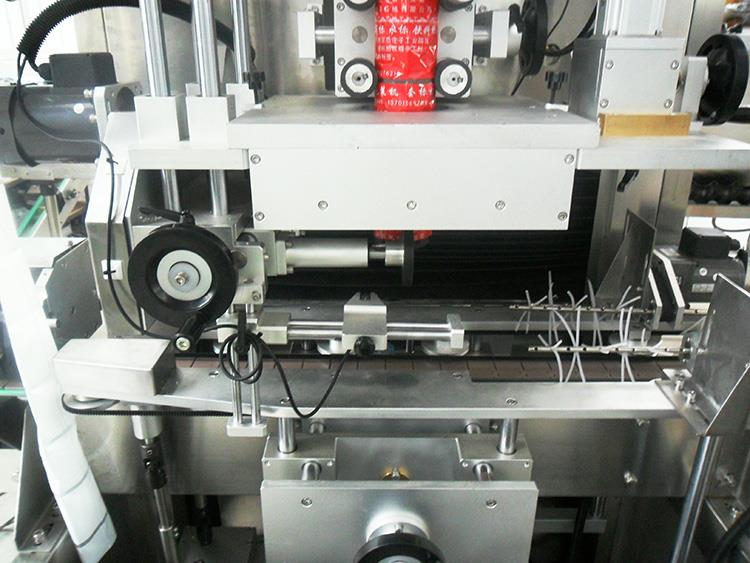

The machine's structure is compact,and suitable for the production line of different direction and different height ,The machine part adopts combination designing of modularization ,and make the machine reasonable ,the height adjustment adopts motors fluctuating,it is convenient to replace the material ,The special cutter head designing ,make the film rolling cut more exactly and reliably.

To meet high speed capacity requirements of wide range customers’, the research & development department of our company makes research and improvement with great care to manufacture this product, VK-460EL, this model the highest velocity of which can be up to more than 600 Bottle per minute; It also employs internationally advanced technology of the same kind.

VK-460EL this model with Double Driving Mechanism Equip with a new-type of label feeding system with double servo drive, high speed response and precision position are achieved.

using gear transmission in China enables machine more stable and suitable for the high-speed production line.

Applicable Types of Bottles: speed of this type machine reaches within 500Bottles-600Bottles per minute; it applies to such food & beverage industries as fruit juices, tea drink, dairy products, pure water, condiments, beer and sports drink and all kinds of other bottle types.

Technical parameter

| 1. | Input Power | 8kw |

| 2. | Input Voltage | 380V/220VAC |

| 3. | Production Efficient | 500-600bottles/hour |

| 4. | Size of Host Machine | L2500mm×W1200mm×H2200mm |

| 5. | Applicable Diameter of Bottle Body | 26-125mm |

| 6. | Applicable Length of Lable | 30-250mm |

| 7. | Applicable Thickness of Label | 0.13-0.35mm |

| 8. | Applicable Internal Diameter of Paper Tube | 5〞-10〞 freely adjust |

Technical Features and application :

1. Label feeding unit, adopt double material shelf which make change of label more convenient and fast. photo electricity check label and no bottle or no label, stop machine automatically and install alarm light will display, also will show on touch screen. Meanwhile equipped with ultrasonic sensor which enables the label feeding stable and fluent and avoid the error label length, label block and other problem when label feeding servo convey the label.

2. Adopted with motor coordinating with double circular arc synchronous belt makes clean down plastic core-rubber-tires synchronously and ensures the label casting stably. Inhibiting device on the screw mandrel effectively control the fault operations and ensures the safety of the center pillar.

3. Bottle carrying unit: Adopted with mechanical transmission to drive the positioning belt on both sides. While changing the whole bottle carrying unit, the down and up, width are all controlled by one hand wheel aiming to synchronously and swiftly adjust.

Clean-down unit: Adopted with electro motion to adjust more conveniently and fast.