Description:

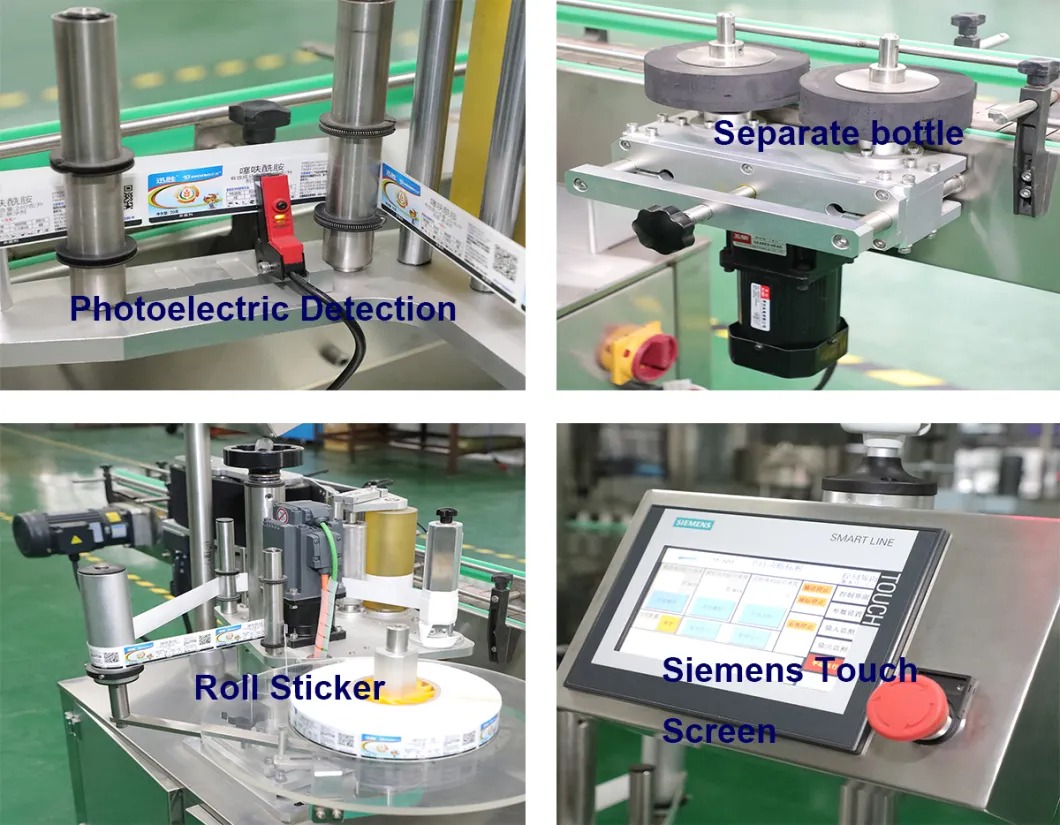

It adopts human-machine dialogue type touch screen: easy to operate, simple, servo control system, adopts PLC program control, and adopts double-distribution wheel structure so that the bottle to be labelled enters one by one. The labeling area ensures the labeling accuracy and the pass rate of each bottle. The marking mechanism adopts an all-round adjustment structure, and the roller labeling mechanism realizes multi-angle adjustment of up, down, left and right, so that adjustment under different specifications is simple and convenient, easy to learn and understand. An encoder is added to the conveying mechanism to synchronize the labeling speed with the conveying speed to ensure the stability of the labeling.

Key Features:

1.Siemens brand PLC control system and touch screen of the control panel.

2. The label tray was made of stainless steel. Not easy to broken and durable.

3. Pressing label by spring plate and sponge scraper that will keep the balance of label.

4. Traction device made by rubber roller, knurl aluminium tube, aluminium alloy, driven by a stepper motor, drawing the label out.

5. Label sensor is imported from famous brand, label measuring is accurate.

6. Label-peeling plate and strengthening device made by stainless steel. when the label passes the plate, the label and release paper are separated: the label sticks to the bottle while the release paper keeps moving. meantime the strengthening device will roll to make the label stick tighter.

7. Release paper recycling device by stainless steel that main to recycle the release paper.

8. The touch screen by English parameters that can be modified or set as your needed directly.

Driving Mold | Servo motor |

Capacity (Pcs/min) | (60-110pcs) Depends on bottle and label size |

Label material | Adhesive sticker, transparent or opaque |

Suitable label size | Width:15-140mm Length:80-300mm |

Suitable bottle size | can customized |

Voltage | AC110V/220V/380V |

Operating direction | left or right |

Labeling accuracy | ±1.0 mm |

Total power | 1.5KW |

Machine size (LxWxH) | 2400mmx1000mmx1750mm |

About Packing:

To ensure our service quality, we will execute the following packaging standards in delivery:

1. All the products before delivery should be tested by assembling and debugging engineers wiped up and then wrapped by stretch film to protect it from moisture. The precision part needs to flexible package.

2. In addition, without standard tools, manual and other documents, and allow ex-factory confirmation sheets, the machine cannot leave the factory All the products will be packed in wooden cases. The exported products use plywood case to pack. The foot margin of equipment fixed tightly to make the machine can experience loading and uploading, the upward mark will be posted on the wooden case.