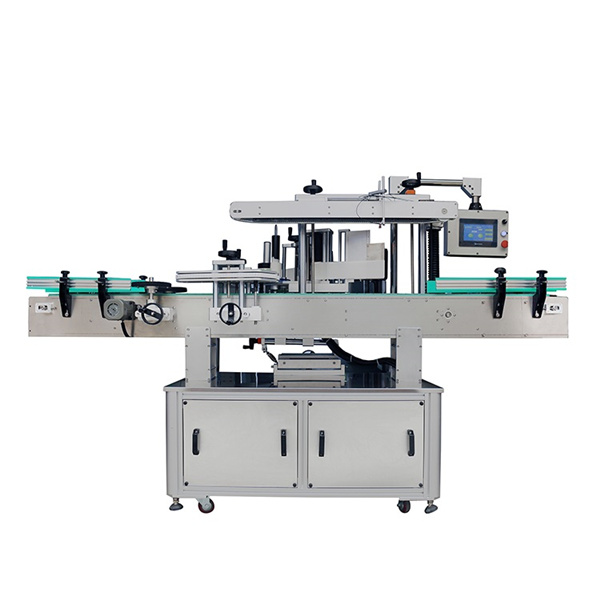

reliable round glass bottles plastic containers wine labelling machines double heads body neck labeler equipment auto

Product features on double heads bottles labeling machines

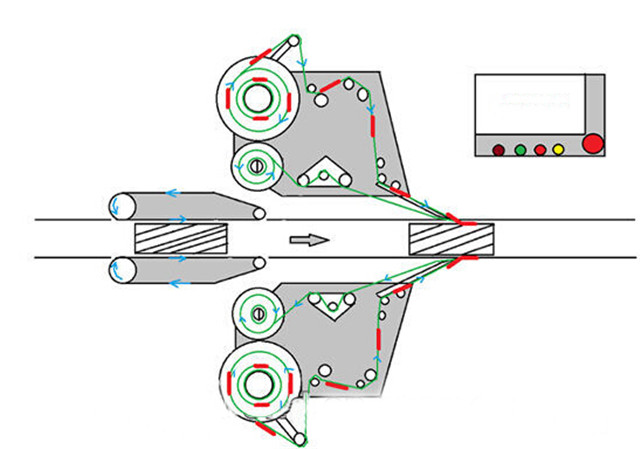

1. The double side automatic labeling machine is suitable for square bottles or flat bottles with double mark or single mark.

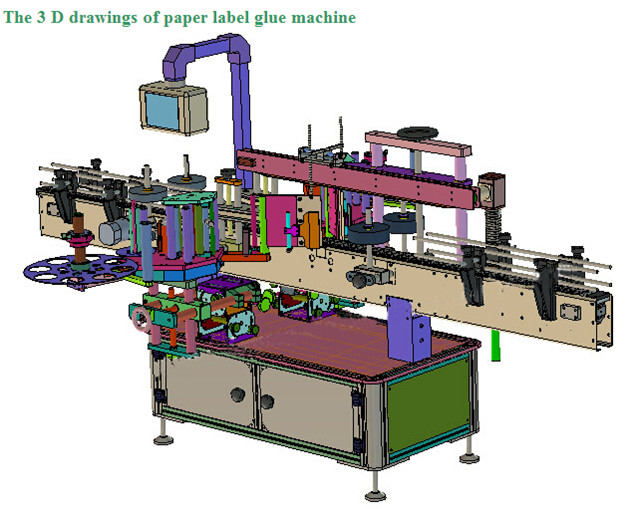

2. The machine is designed with large-power and strengthening structure. The shape belt can be inclined ,and the labeling head can be adjusted at eight orientations ,so the machine can be adjusted successfully in several minutes for any bottle.

3. The pressure between the active axle and the press roller can be adjusted ,so the running direction of the label can be adjusted freely .the label is only pressed flexibly without causing any distortion.

4. The labeling head adopts the structure of the double press rollers .it guarantees that the label is pulled tightly but isn't broken because of the underneath paper die-cutting, the separated clutch makes the strain more balanced.

5. The touch screen based human interface in Chinese and English with the online helping system makes it easy for operate the machine for the workers .the press belt is geared into the main transporting line ,so it makes the two transporting lines work in synchronous absolutely .

6. The machine apply the famous server motor, so it realizes real closed loop controlling and it avoids the phenomenon of "the blind man walk" when the machine apply the stepper motor. The shape structure is designed specially, so the labeled thing is able to be located and labeled precisely.

7. The multi channel encoder detects labeling position precisely at high speed. The label is pressed by a flap after applying on bottle and is pressed by the active and passive sponge rollers .so when the label is stuck it hasn't any air bladder. it is especially applicable to the crystal bottles labeled with transparent labels.

8. The optional air driving and roller labeling set can label round bottles precisely.

Types of bottles

Chart of Double-head automatic Sides plus round bottle labeling machine

Technique data

| Production speed | 40m/min(80-200PCS/min) |

| Labeling accuracy | ±1mm |

| Label max width | 200mm |

| Bottle diameter | Thickness≤30mmheight≤500mm |

| Label inner diameter | Φ76.2mm |

| Label outer diameter | Φ350mm |

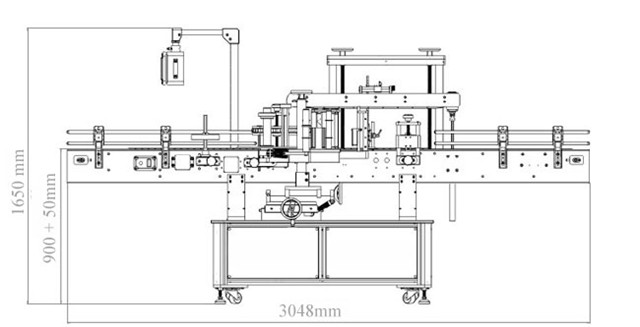

| The height of the conveyor line chain plate to the ground | 900mm±50mm(can be produced according to customer requirements) |

| powe | 380/220V 50Hz 3000W |

| Operating pressure | 3-5kg 30L/min |

| weight | 400kg |

| size L*W*H | 3048*1400*1650mm |

Main configuration

| NO. | Name | Brand | Qty | Remark |

| 1 | Servo motor | Delta | 2 set | Taiwan |

| 2 | servo driver | Delta | 2 set | Taiwan |

| 3 | Touch screen | WECON | 1 set | Shanghai |

| 4 | Transport motor | Zhujiang | 1 set | Shanghai |

| 5 | Label electric eye | TECO | 1 set | Taiwan |

| 6 | EUT electric eye | DataSensor | 2 set | Italy |

| 7 | PLC | Panasonic | 2 set | Japan |

| 8 | Stainless steel material | Panasonic | 1 set | Japan |

| 9 | Stainless steel cabinet | 304 | GB | |

| 10 | Label electric eye | JJZ | 1 | Shanghai |

Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse,

misapplication, storage damage, negligence, or modification to the Equipment or its components. Also the easy broken spare part is not included in the guarantee)

Installation: after the machine arrive your factory,if you need, our technician will go to your place to install and test the machine and also training your worker to operating the machine (The time of train depend on you worker). The expenses (air ticket ,food , hotel,the travelling fee on your country) should be on your account; you need paid for the technician USD100 per day. also you can go to our factory to do training.

After service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible.The cost should be in your account.