Introduction

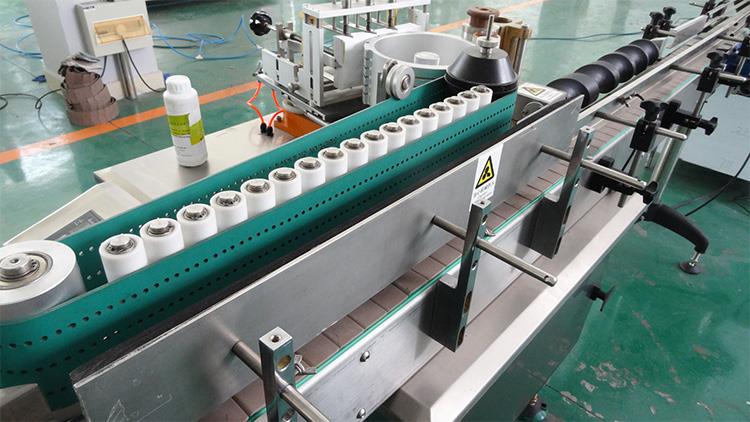

This wet glue labeling machine also called paste labeling machine, Suitable for labeling machine for glass bottle and plastic bottle, can automatically spray paste for common label, and label on bottle surface. Widely used in beverage bottle ,medicine bottle and wine bottle, this machine suitable for different bottle type and label size. For size similar bottles, no need change any parts, just need adjust is ok. Frequency conversion adjust speed, running speed also adjustable.

Technical parameter

| productivity | 40-120 bottle/min( relate to material and label size) |

| direction | from left to right(Could be customized) |

| Roll inside(mm) | 76mm |

| Roll outer side diameter(mm) | 350mm |

| Label size | (L)20-180mm (H)10-150mm |

| Material size | (L)30-200(W)40-180(H)40-260mm |

| Labeling accuracy(mm) | ±1mm |

| Power supply | AC220V 50Hz/60Hz 1500W |

| Net weight | 550kg |

| Contour Sizes | 2400*1300*1500mm |

Technical Features and application :

1. This machine with pneumatic supply paste pump, paste can recycled to use, convenient to operate, accurate labeling, is most advanced paste labeling machine.

2. The whole machine labeling process is simple. Label evenly coated with cold glue, refuse to waste, label firmly and not fall off, no wrinkle, ribbon stripes, beautiful appearance.

3. Glue Reservoir is designed in high-precision, the rollers takes glue evenly without drip and labels can be pasted solid and flat with low error rate.

4. Hign accuracy rate of labeling by vacuum belt label transport. it is equipped with air-powered glue pump and label shortage warning device

5. It can work independently or by connecting to the production line.

6. Its operation is flexible and convenient, the label sticking is correct and smooth, and it is a most advanced glue labeling machine in the market recently.

Main Feature:

1. Applicable to the pharmaceutical, food, cosmetic and other industries, the circumference of the round object and high precision are (double standard) and the fixed point and position on the back label; Can also meet with taper product labeling requirements.

2. The advanced affinity man-machine interface system, easy operation, complete function, has the rich online help function

3. Unique bottle at three-point position, avoid to linear labeling machine labeling bottle is irregular, and the bottle is not caused by the error of vertical labeling skew, then it let labeling more accurate, beautiful, caresses

4. Automatic photoelectric detection, it has the function that nothing come from conveyor and no stick label and without label automatic correction or alarm automatic detection function, prevent leakage and waste

5. The machine structure is simple, compact, easy to operation and maintenance