It is suitable for the single / double / multi-sides of the round bottle, square bottle and irregular bottle.

Before we make the machine we will design the rotary labeling machine according to the customer's requirements from our engineer technical department

►The labeling effect is good:

The biggest characteristic of this equipment is the imitation of human labeling, completely subvert the traditional way of labeling, thoroughly solved the problem, spherical stick mark wrinkle make possible differentiated product labeling.

►High positioning accuracy:

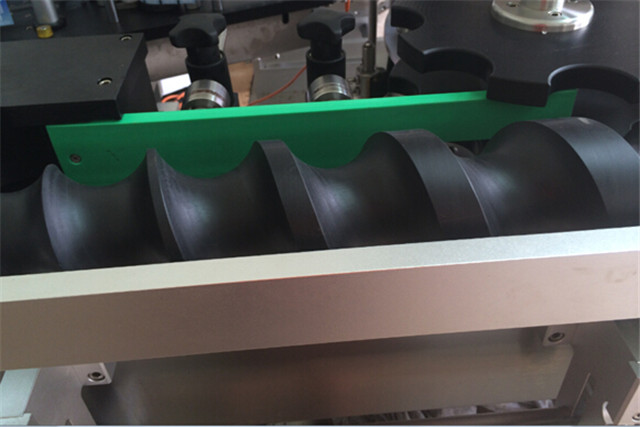

Using mechanical rotating positioning, advantage of the characteristics of the bottle itself looking for anchor point, greatly improve the stick mark stability and accuracy.

►Easy to adjust:

Send the device can be adjusted 8 gears, especially suitable for a bottle type of the taper, and change the different size of the product is simple and easy to adjust, need not use tools.to avoid bad labeling affect caused by machine shaking, all direction adjusting modules will be locked after the machine finish adjusting. So it will insure the production process smoothly and the labeling location consistently.

►Good stability.

A. Machining parts material guarantee: The machine is made of high quality raw materials. The parts use high quality aluminum, steel and imported nylon.

B. Advanced processing equipment: main parts professional factory uses in all Polytechnic high precision processing to complete, the main parts in the machining process will be used in the highest level of detection methods for quality control, in order to obtain the highest quality and highest-precision parts, reduction of machine vibration at high speeds

C. Using famous brand spare parts.

D. Using world first-class brand electrical accessories.

E. Novel structure. Main designers have more than 10 years design experience in this field. Each component are through strict aging test.

►Efficient production:

The speed is up to 24000bottle/hour. High speed labeling fluency .

It can match front and end seamless butt joint and improve production efficiency.

Types of bottles

Technical parameters

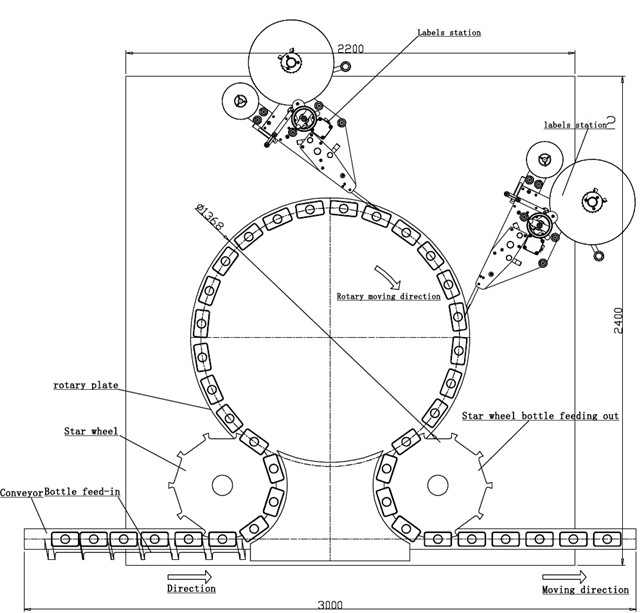

| Labeling position | 12,15,18,24 position, according to the customer's production requirements |

| Production speed | 0~24000( PCS/H) Can do 1 to 3 labels |

| Labeling accuracy | ±1mm |

| Bottle diameter | Φ40~100 mm,Bottle High:20~380mm |

| Adhesive label width | 20~180mm |

| Adhesive label High | 20~200mm |

| Label outer diameter | Φ450mm |

| Label inner diameter | Φ76.2mm |

| Power | 380V 50Hz 5000W—7000W |

| Outline Size(L*W*H) | 2850*2600*2000mm(24 position) |

| Weight | 2000KG-5000KG, Depends on different models |

The details of automatic rotary positioning labeling machine

Labeling position:12,15,18,24,according to the customer`s production requirements

Electrical component list

| NAME | SUPPLIER | BRAND COUNTRY |

| PLC | SIEMENS | GERMANY |

| INTERFACE | HITECH | TAIWAN |

| SERVO DRIVER | Mitsubishi or YASKAWA | JAPAN |

| SERVO MOTOR | Mitsubishi or YASKAWA | JAPAN |

| CONVETER | DANFOSS | DENMARK |

| AC CONTACTOR | TELEMECANIQUE | GERMANY |

| UNIVERAL CHANGE SWITCH | MOELLER | GERMANY |

| EMG BOX | TELEMECANIQUE | GERMANY |

| EMG | TELEMECANIQUE | GERMANY |

| BOTTLE SENSOR | KEYENCE | JAPAN |

| LABEL SENSOR | SICK | GERMANY |

| SWITCH POWER | M/W | TAIWAN |

| CONVEYOR MOTOR | PANASONIC | JAPAN |

| SMALL MOTOR | PANASONIC | JAPAN |

| GEAR BOX | PANASONIC | JAPAN |

| REDUCER | PANASONIC | JAPAN |