1. The Scope of Application:

Applicable for round objects with smaller diameter and can not stand when labeling, such as ampoule ,vials,blood collection tube, pen, sausage and so on.

2. Working principle:

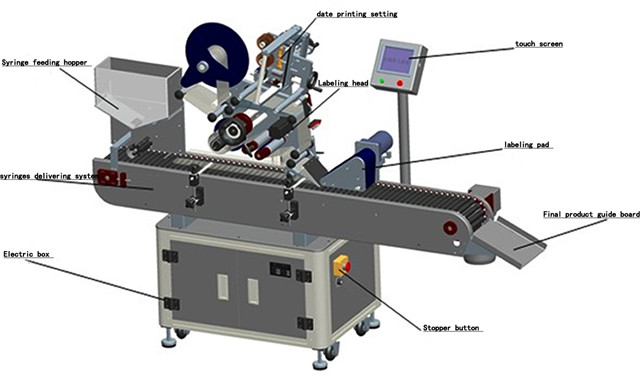

Bottle is set level and fed into conveyor by separator wheel and righting bottle by righting device. When sensor detects bottle, will send a signal of dispensing label, the base paper rolls back after bottle is labeled, a roller press down the label for label smoothness.

3. Device Characteristics:

Adopt mature technology PLC control system,operation is stable and high-speed;

Using touch-screen control operating system, simple and efficient;

Advanced technology of pneumatic coding system, print the batch number and expiry date clearly;

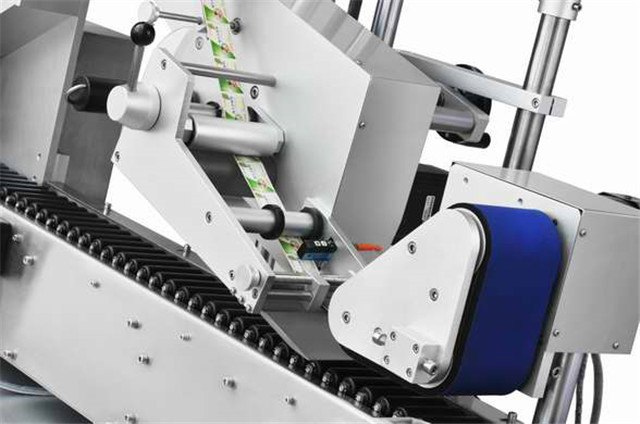

Transmission-type rolling bottles, make sure the labels attached more firmly;

The damaged rate of bottle is less than 1/200000;

4. Device Advantages:

Imported electric elements, stable performance, low failure rate;

Adopt photoelectric detection, PLC control system, software operation, conveyor belt, label accurately with high precision;

No bottle no label, automatic alarm when achieve leakage label.

The whole machine use material S304 stainless steel and anodized senior aluminum alloy.

5. Technical Parameters

| Capacity (pcs/min) | 50-230 |

| Driving Mode | Servo motor |

| Conveyor Speed(m/min) | ≤35 |

| Label Specification | adhesive sticker,transparent or opaque |

| The application of label object | diameter:12-24mm Height:25-95mm |

| The application of label | Height 20-70mm Length 25-80mm |

| The inner diameter of label roll | 76mm(min) |

| The outer diameter of label roll | 350mm(max) |

| Printer use air | 5kg/cm ² |

| The power of motor(w) | 300W |

| Voltage | AC220V 50/60HZ Single phase |

| Size appearance(mm) | 1800(L) 700(W) 1270(H) |

6. The Main Electrical Configuration Table:

| No | Name | Model | Unit | Brand |

| 1 | PLC control system | 6ES7212-1A | 1 Set | SIEMENS |

| 2 | Touch-screen | 6AV6648-01A | 1 Set | SIEMENS |

| 3 | photoelectric sensor (check label object) | FS-V11/-FV-35FA | 1Set | Japan KEYENCE |

| 4 | Photoelectric sensor(Check opaque label) | GS61 | 1 Set | German Leuze |

| 5 | Servo motor | 2004-RZ08BAIAN | 1Set | America AB |

| 6 | Drive | 2003-CSD3-08BX2 | 1Set | America AB |

| 7 | Main transport motor | 90W1:30 | 1Set | German JSCC |

| 8 | Press bottle motor | 40W1:30 | 1Set | German JSCC |

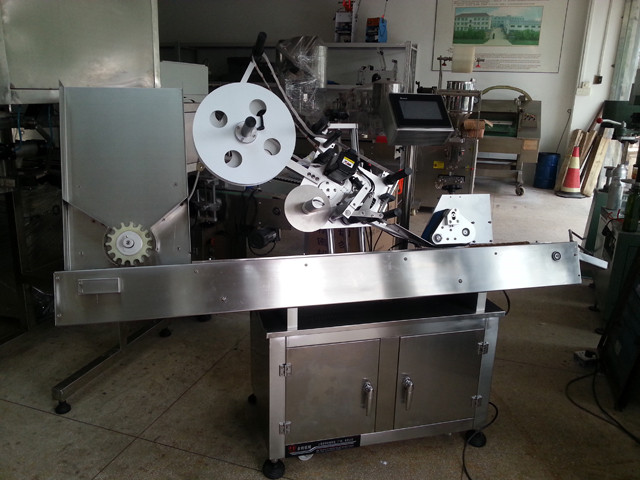

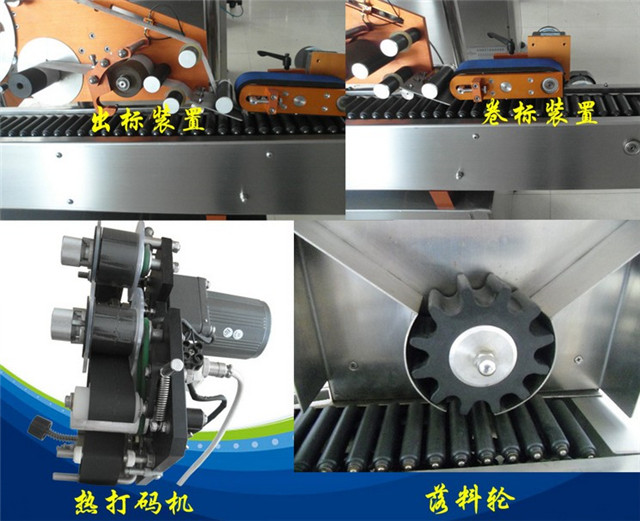

Horizontal labeling machine displayed in details

FAQ

1. What is your Machine Design?

1.1 Fully automatic Syringes Bottles Horizontal Labeling Machine Wear-resistant label rolling mechanism, use

Polyurethane material, not wear and tear.

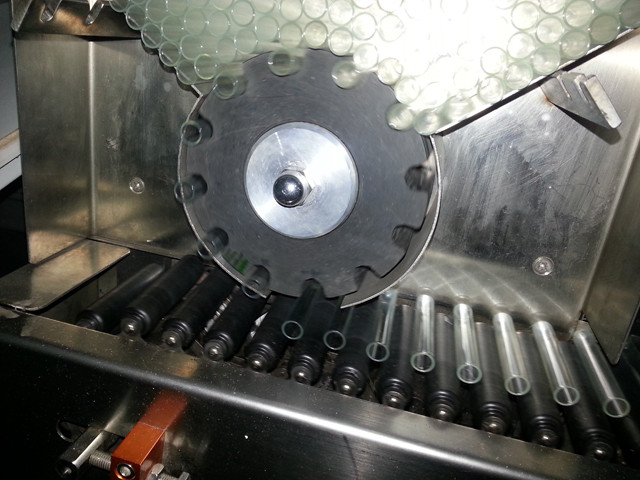

1.2 Advanced screw wheel feeding mechanism, easy, steady, reliable, not broken bottles.

1.3 Use imported bearings for transporting wheels, make the bottles rolling agilely, ensure the labeling

Quality.

1.4 Durable frame and other parts, standard, changeable, can work 24hours.

Case is made of SUS304 stainless steel and T6 aluminum alloy, never rust, meets GMP standard.

1.5 Rolling wheel press bottle, make the label more fasten.

1.6 Label sync orientation mechanism, precision ± 1mm

1.7 Multipoint E-stop button fixed on the suitable position of the production, makes it more

Safe, smooth.

2. What's payment terms, trade terms you accept?

Usually we appreciate T/T 30% deposit, then 70% balance is paid before shipment, we usually offer FOB (Shanghai) price.