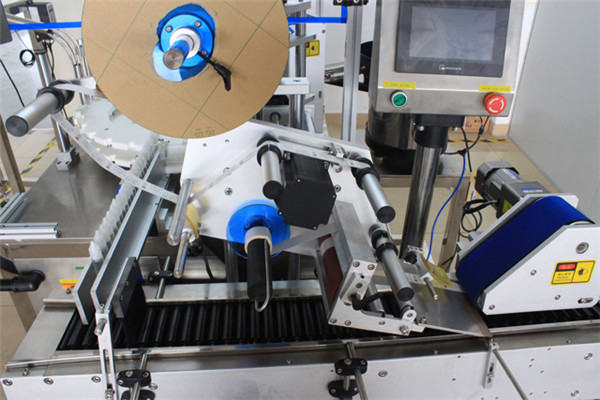

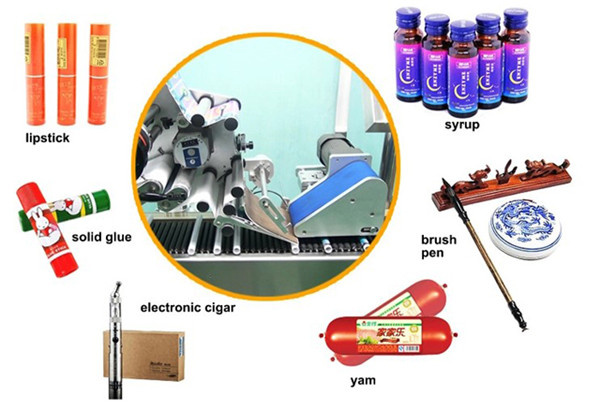

This machine horizontal labeling is basically satisfied for all kinds of products that have label requirements, especially used for small volume and multi-species of products labeling. It can greatly improve labeling production and reduce the cost of equipment investment.

Horizontal Wrap Labelling equipment are used to partially or fully wrap unstable products by laying the product on its side, supported by idler rollers mounted to attachment chains. This is by far the most accurate means of labeling product as it is supported within the roller "cradle".

Parameter of horizontal bottle labeling machine:

Speed(pcs/min): 60-260

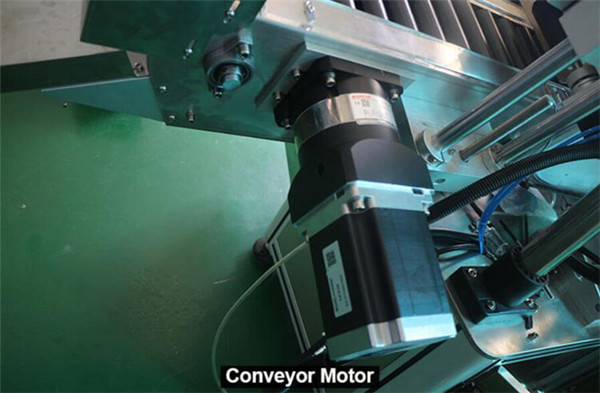

Driving Mode Servo control system

The size of bottle Out diameter: 12-24mm,

Height: 25-95mm

The size of label Height: 20-70mm Length: 25-80mm

The inner diameter of label volume (mm): 76mm

The outer diameter of label volume (mm): 350mm(max)

Power of motor (w): 300W

Power supply: AC220V 50/60HZ single phase

Dimension (mm): 1800 (L) * 700 (W) * 1270 (H)

Easy to operate and maintain,workers can operate dependently only by simple training;

The transmission part is wrapped, the circuit and the gas path are arranged separately, so as to avoid the abnormal occurrence, it’s safer;

Compact structure and small floor area, it’s easy to move and install;

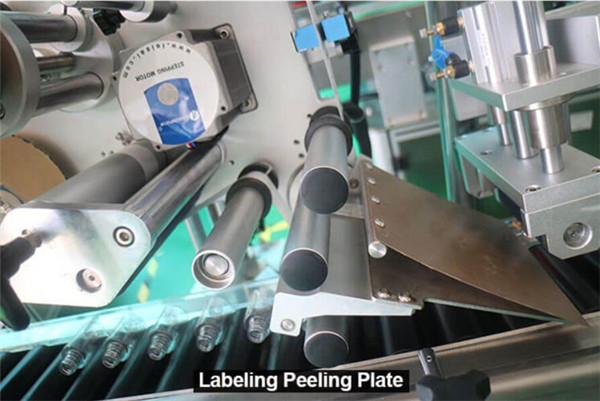

The labeling is smooth, not wrinkle, no bubble, high precision and good stability;

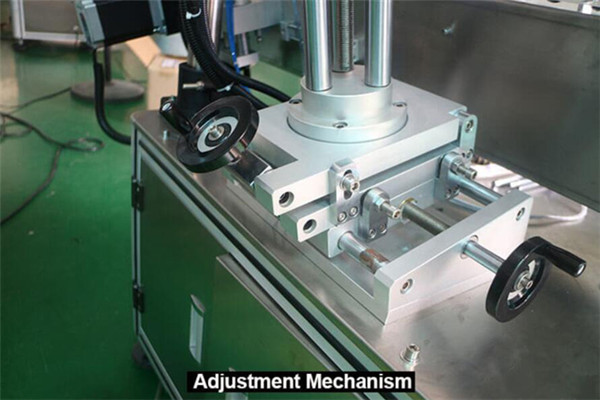

The ingenious design of the structural combination of mechanical adjustment and the winding of label, it makes the different products adjusting and label winding become more simple and save time

Purpose: Achieving affixed with a adhesive label in products flat, curved, circle surface, concave and convex .

Function: Improve the efficiency of labeling and pad pasting, the position is accurate, the quality is good and the stability is high.

It can avoid many artificial problem, such as low efficiency, irregular position, label skew, blister and fold, etc;

Effectively reduce the cost of products, improve product identification aesthetics, enhance the competitiveness of products.

Suitable for the unstable circular cylindrical objects, semi circle labeling, horizontal transmission, horizontal labeling way, increasing stability, improving the labeling efficiency.

Optional printer or inkjet coder attached to the labeling applicator, it can print on the label production date, batch number and barcode printing information.

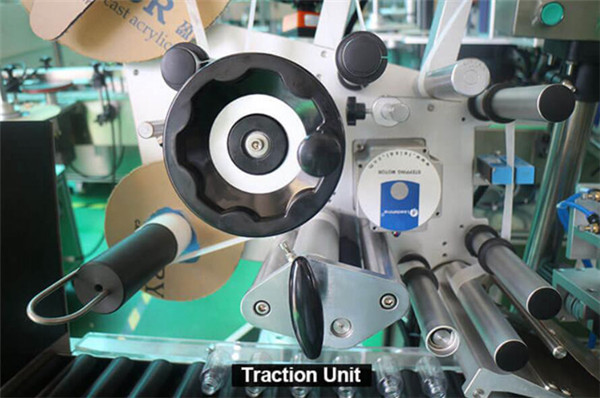

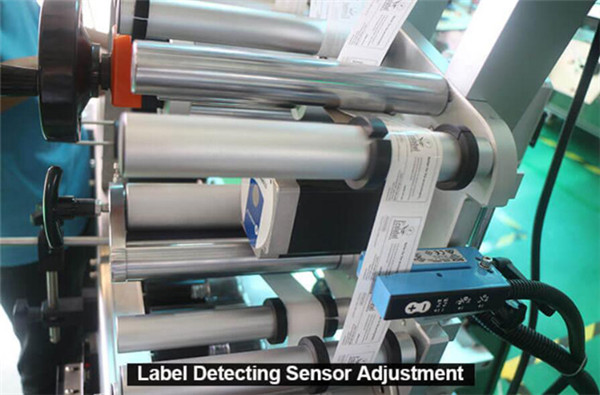

Core working principle: The sensor detects the product passing through after the product is separated by the bottle dividing mechanism, and then returns the signal to the labeling control system, which controls the motor in the appropriate position to send the label to be attached to the labeling position. The product flows through the labeling device; the labeling tape rotates the product; and the label is rolled over; thus a label’s sticking is completed.

Application (Automatic Horizontal Round Labeling Machine):

Automatic Single Hopper Horizontal Round Labelling Machine is suitable for the foodstuff, medicine, cosmetics and other light industries of the planiform label.

Features (Automatic Horizontal Round Labeling Machine):

1. The PLC control combined with touch screen providing user friendly operation and high precision.

2. The memory of 60 groups of labeling specifications can exchange the production line quickly.

3. The equipment is up to the mustard of GMP requirements and made of SS304 which is treated by anodic of high-class aluminum alloy.

4. The machine has many functions such as count, attach label and so on.

5. The labeling position of height and angle can be adjusted.

6. The modular-design makes this machine suitable for operation together with other machines or in a production line.

7. The machine can be used to label the body and bottleneck at the same time with some changes.

8. The hot printer and transparent label sensor are optional.