Product introduction:

It is intended mainly for sticking label outside the side face of round or quadrate bottles. The machine words stably and reliably, which leads to smooth labels, clearly printed dates and batch numbers(the printer allows three rows of characters). This machine is provided with a multiple control system, which assures automatic stop at the lacking or breaking of labels as well as at the lacking of bottles. This product conforms to the specifications of GMP absolutely. Which is widely used in pharmaceutical, foods and chemical industries

Mark: some equipment have no coding machine

Applicable bottle types

Two sides labeling machine (non -dry type) is our company's new product. apply to square bottle .flat bottle .square bottle of food . medicine, chemical, and other industry.

Feature

(1) This machine adopts PLC control system. So the machine operation is more stable and high speed.

(2) Operation system adopts humanized touch screen ,easy to operate.

(3) Choose the servo motor imported to prove the speed and accuracy.

(4) Machine frame and parts are 304 stainless steel.

(5) No bottle no label ,and no label missing ,no labeling blocking .has alarm

(6) In advance function . easy to operation . compact structure.

(7) Easy to Exchange bottle. Do not need exchange any parts.

(8) Electrical appliance imported ,stable performance. Reduce the failure rate.

(9) Not only Suitable for single ,but also production line .

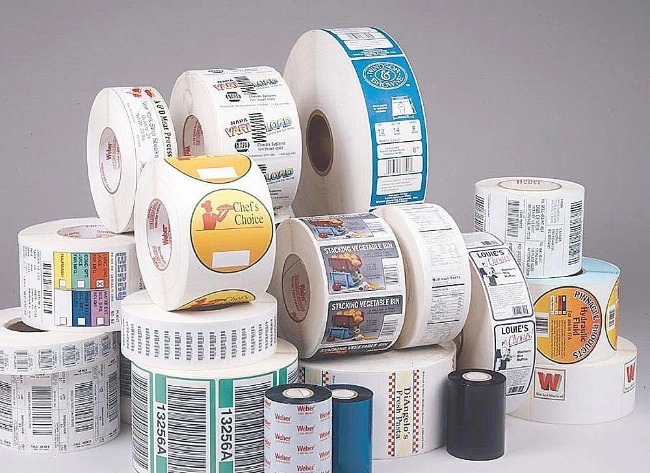

Label type:

Technical Specification

| Driving way | Servo system |

| Operation direction | According to client requirement (left or right) |

| Out put labeling speed(B/H)) | 2000-18000( according to bottle size and label size) |

| Accuracy | ±1.0mm(as per bottle shape) |

| Apply to labeling | Sticker ,paper |

| Labeling internal diameter(mm) | 76mm |

| Labeling outer diameter(mm) | 380mm |

| Apply to bottle diameter(mm) | 25-120mm |

| Apply to bottle high(mm) | 30-180mm |

| Apply to labeling size | High 15-100mm length 20-300mm |

| Weight (kg) | 175 |

| power(w) | 1000W |

| voltage | AC220V 50/60HZ single phase |

| dimension(mm) | 2800(L)×1700(W)×1550(H)mm |

Electrical appliance configuration specification

| No | Item | Brand | Quantity(set) | Note |

| 1 | PLC | mistubishi | 1 | JAPEN |

| 2 | Touch screen | weinvew | 1 | TAIWAN |

| 3 | Frequency converter | aidli | 1 | TAIWAN |

| 4 | Paper collecting motor | aidli | 2 | TAIWAN |

| 5 | Paper feeding motor | aidli | 2 | TAIWAN |

| 6 | Paper collecting photoelectric | leuze | 2 | GERMAN |

| 7 | Paper feeding photoelectric | leuze | 2 | GERMAN |

| 8 | Servo motor | mistubishi | 2 | JAPEN |

| 9 | Servo motor driver | mistubishi | 2 | JAPEN |

| 10 | Paper collecting gearbox | aidli | 2 | TAIWAN |

| 11 | Paper feeding gearbox | aidli | 2 | TAIWAN |

| 12 | Conveyor servo motor | mistubishi | 1 | JAPEN |

| 13 | Upper pressure servo motor | mistubishi | 1 | JAPEN |

| 14 | Conveyor servo motor driver | mistubishi | 1 | JAPEN |

| 15 | Upper pressure servo motor driver | mistubishi | 1 | JAPEN |

| 16 | Upper pressure reducer | East star | 1 | CHINA |

| 17 | Conveyor reducer | East star | 1 | CHINA |

| 18 | Separate bottle motor | aidli | 2 | TAIWAN |

| 19 | Correcting motor gearbox | aidli | 1 | TAIWAN |

| 20 | Separate bottle motor gearbox | aidli | 2 | TAIWNA |

| 21 | Separate bottle Frequency converter | aidli | 1 | TAIWAN |

| 22 | Relay | omron | 5 | JAPEN |

| 23 | Fiber amplifier | leuze | 1 | GERMAN |

| 24 | Fiber | leuze | 2 | GERMAN |

| 25 | Label detection photoelectric switch | leuze | 2 | GERMAN |